Maintaining Power Tools

Maintaining power tools is essential. Doing so not only helps extend their effective service life but increases your chances of finishing that project.

Clean Contacts for Motors

Most small power tools have two "brushes," solid blocks of carbon graphite that conduct electricity to the motor's spinning armature. Friction gradually wears these brushes away, and if they're not replaced, the motor loses power and eventually quits. You can tell it's time for new brushes when you see lots of arcing-small, harmless sparks inside the motor housing as the tool is running.

Replacing worn-out brushes is easy if your tool has brush covers-the two black caps on opposite sides of the motor housing. Always replace both brushes at the same time. If your tool doesn't have brush covers, you'll have to let a repair shop do the work.

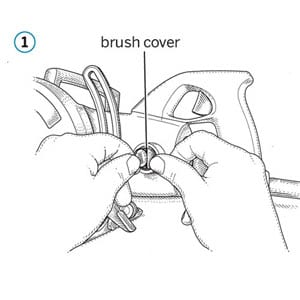

Brush away any dust and debris from the brush cover, then unscrew it with a flat-blade screwdriver or coin. As the cap loosens, rest a finger on it; the spring-loaded brush can pop loose suddenly.

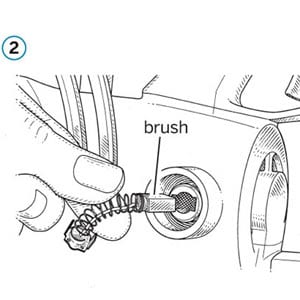

Pull out the brush and its attached spring. Vacuum the cap area to remove any sawdust that may have come out with the old brush, then slip the new one in. Tighten the cap against the spring and test the tool.

Tip: Tempting as it is to blow away dust with a blast of compressed air, I don't because it can drive particles into the switch or other sensitive areas.

Power-Tool Care Checklist

- Brush, vacuum, or wipe off dust; the same goes for battery chargers

- Inspect power cords for nicks; replace cords with frayed jackets or exposed wires

- Check that all moving parts work smoothly

- Tighten any loose screws or bolts; put a drop of Loctite on the threads to keep them in place

- Test a circular saw's blade brake; it should stop the blade when you release the trigger

At The End Of The Year

- Look for cracks in motor housing; don't use a tool with cracks larger than a hairline

- Lubricate parts where metal rubs on metal

- File any nicks in the shoe plates of jigsaws and circular saws

- Flatten bent shoes with Vice-Grips; use a combination square to check that the shoe is perpendicular to the blade

- Follow the instruction supplied with each tool's manual for specific maintenance procedures